Overview of what’s going to be covered:

1. Creating a team of different disciplines (cross functional)

2. Implementing robust containment processes

3. Verifying your quality management systems are heavily utilized by the entire company on a day-to-day basis.

-

When it comes to root cause analysis, many companies fail to look deeply into their current established procedures (deep dives)

-

Focus mostly on what happened with personnel, but seldomly look or ask questions as to what in the process failed (key)

-

Keeping quality management systems very vague just to “pass” AS9100 audits

-

Not focusing on the purpose of the quality management systems, which is to protect their company from having nonconformances with root cause analysis escape their facility.

Watch the below webinar or read below how to protect your company from nonconformances with root cause analysis!

Corrective Action

In order to understand customer complaints, you have to understand what the definition is of corrective action. Corrective action is defined as the process of reacting to an existing product problem, customer complaint or other nonconformity and fixing it.

What is an RRCCA?

-

Relentless Root-Cause Corrective Action(s)

-

Relentless: oppressively constant; incessant

-

“Relentless Root Cause Analysis engages with a process to enable the rapid and persistent understanding of the fundamental reasons for the breakdown or failure of the process that, when resolved, prevents a recurrence of the problem.”

-

Important to Note: The root cause is the fundamental breakdown of the process!

Corrective Action Program

When conducting an internal audit, it is vital that whomever is auditing the quality department that they look into the conformance reports to make sure the company has an effective corrective action program in place. Below will insure that your company has a robust process.

-

Implementing an effective and fully compliant Corrective action program is an 8 part process (9 if incorporating ARP9136)

-

Each step must be thoroughly documented!

-

Properly documented actions provide important historical data for a continuous quality improvement plan and are essential for any product that must meet the regulatory requirements demanded by FAA and AS/ISO.

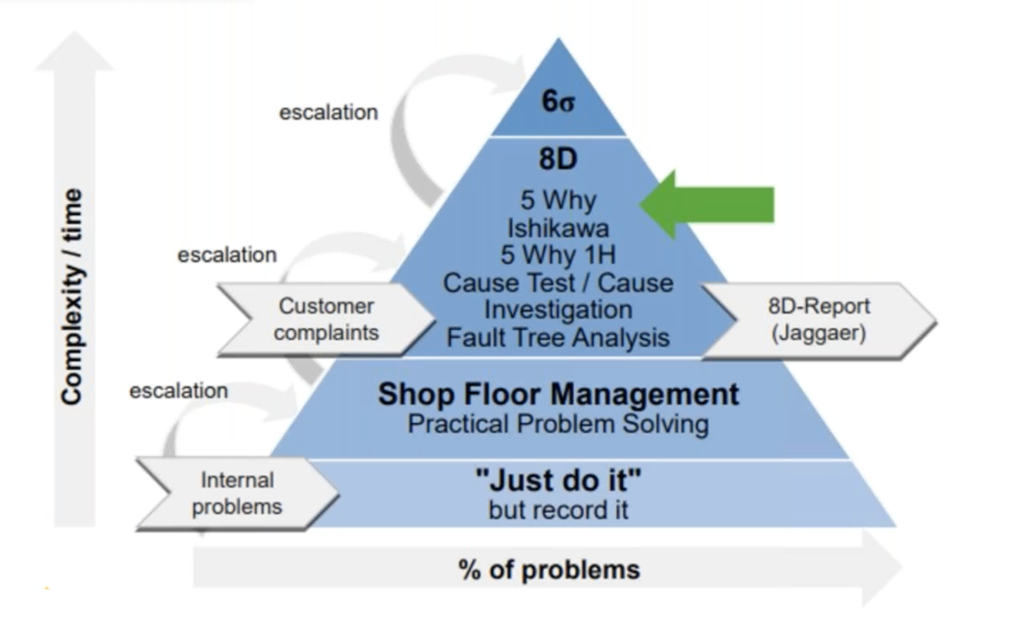

The Problem Solving Pyramid

The problem solving visual below is a great tool to hang on the shop floor to use as a reminder on a daily basis and to help determine a root cause.

8D Methodology Vs. 9S Methodology

8D Methodology is coming out of the aerospace standard 13000. Below is important information within the standard that will help with root cause. You can learn more in detail about this here:

1.D1: Formation of a problem-solving team

2.D2: Problem description

3.D3: Containment action

4.D4: Root cause analysis

5.D5: Potential corrective action

6.D6: Implement corrective action

7.D7: Take preventive action

8.D8: Closure & team celebration

9S Methodology:

- Start immediate containment actions

- Build the team

- Define the problem

- Complete and optimize containment actions

- Identify the root cause(s)

- Define and select permanent CAs

- Implement permanent CAs and check the effectiveness

- Standardize and transfer the knowledge across business

- Recognize and close the team

3 ways to protect your company from nonconformances with Root Cause Analysis

1st Approach is to Create a Collaborative Environment:

-

Creation of a team that will review the non-conformance

-

Various disciplines

-

Team Leader

-

Access to all processes and company data

-

Senior Leadership engagement and support

-

AS9100, section 5

-

AS9100, section 10

2nd Approach is to Implement a Robust Containment Processes

-

AS13000

-

“D0” or “Step 0”

-

What is D0?

-

“Stop the bleeding”

-

QMS Containment procedure!

3rd Approach is to build an effective QMS into Company Culture

-

AS9100, section 9.2

-

Robust Internal Audit program

-

Quality culture

-

Monthly or bi-monthly QMS spot audits

-

Quarterly assessments of QMS processes

-

Customer Contract Reviews

-

Engagement of Leadership

-

RRCA

Contact Us

Gain the skills and knowledge you need to identify and address problems effectively.

There is so much information when it comes to Root Cause Analysis 8D methodology and it isn’t always easy to understand. We can make it simple through our trainings. Contact a team member who will be your guide and help you reach your goals by calling 919-635-5581.